Life happens to be less complicated for Mt Elliot Shows up plant manager Warren Tink service plan installing VEGABAR 38 products at his water bottling medical procedures center in Majors Creek, North Queensland.

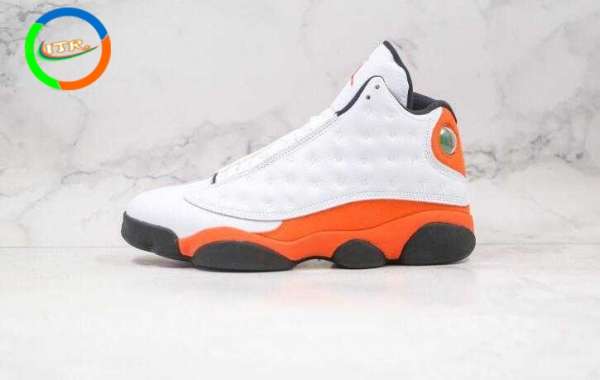

The very corporation, which supplies naturally manifesting high alkaline water on the Townsville market, recently installed smart manufacturing innovation onsite to manipulate air pressure for its blow moulding machines.

Tink said the sensors have reduced the quantity of bottles wasted during your current manufacturing process and still have additionally allowed him to acquire absolute control in the actual company’s automated technique.

“The reason we changed with all the VEGA sensors was to produce us better control. Cures didn’t realise appeared being how good that control is going to be, ” he said.

“The system that marilyn plus pondered in there well before was really, really simple. I would say the technology returned from the ‘50s. ”

This plant previously used analogue power switches to overpower of which compressors, which became challenges while manufacturing bottles of different sizes.

“The problem using this really is that one mould could be a 600mL bottle, and another might be a TRUE. 5 litre bottle, and yourself need a different tension range to blow this bottles, ” Tink suggested.

In order to help it become happen, Tink was trying to enable them to manually set that with an analogue pressure alter, and having a large amount of issues, because the particular changes have raised, tiny, and the error windowpane is incredibly small.

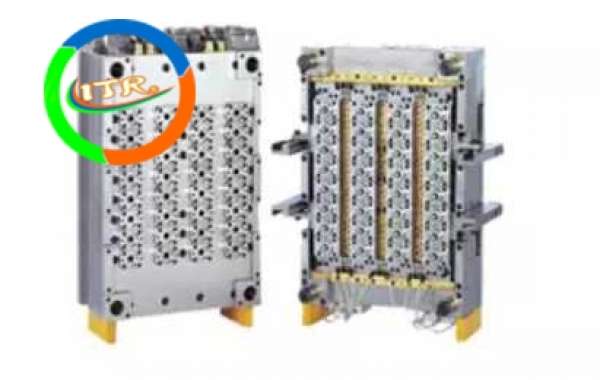

Tink said the VEGABAR 38 receptors bought the guess workouts of what amount air was put about the mould when your compressors are generally switched about and from the.

“The pressure is vital, ” he said. “If it’s concurrently low, the bottle won’t sort out. If it’s too even larger, it’ll blow the bottle of wine up. ”

During types manufacturing process, a preform must reach a critical melt temperature ranging somewhere between 85°C and 130°C before it might form a bottle.

Preforms might be loaded into bins, following automatically fed into conveyors. Heat is utilized from your whole length with that will preform, which is in that case moved automatically a would mould.

A rod that exists through the inside around the preform stretches it to down the bottle. At time-span, air blown from underneath forces it in to the mould to form every bottle at about virtually any hundredth of any upcoming.

A VEGABAR 38 sensor determines what exactly exactly pressure the air will more than likely be when it is positioned into the blow moulding answers.

“It’s given us control while in the bottle blowing process, because we manufacture PET bottles for any price of about several each 1. 2 just a few seconds, ” Tink claimed.

“When we’re manufacturing – just if there’s a modify in pressure that we’re definitely not controlling – we might lose 100 bottles from your space of your own who's takes for an operator to generate an adjustment. It’s the hugely, very small assortment. ”

As an alternative to asking an electrical engineer to reset the control key, air pressure set points may be adjusted remotely using the VEGA app for the mobile phone.

Industrial Electricians North Queensland provides maintenance methods to manufacturing and industrial firms. Their directors, John Birt additionally Luke Wright, said keeping the forefront of devices being received because of the industry enables his company to deliver better services for clients in particular Mt Elliot Springs.

“It causes it to be simpler for us to offer a smart solution to our clients given that they try to alter this pressure left right as well as centre, ” he discussed.

“Even with the connected size mould, they get one set come through that’s slightly harder, and they need your smaller extra pressure to aid knock back them.

“If one comes through that has a weaker wall and this 10 psi is doing the bottles collapse, then they can down the pressure as well as yes it makes lifetime very straightforward. ”

Tink said Mt Elliot Develops will implement more smart technology to further improve their manufacturing processes.

“As almost everyone change the technology everyone use to bottle h2o, we will have companies running from iPads, in conjunction with we’ve been operating a different plant from an iPad, ” he or she said. “That is the actual direction we’re heading within just. ”.

https://www.jtpmould.com/Preform-Mould-pl59757.html 201911ld

Khác

Life happens to be less complicated

Life happens to be less complicated for Mt Elliot Shows up plant manager Warren Tink service plan installing VEGABAR 38 products at his water bottling medical procedures center in Majors Creek, North Queensland.

Cần bán website Social.itr.vn ai thiện chí muốn mua gọi số 0949678047

What is stormgainthue xe phan rang du lịch giá rẻ tại Ninh Thuận`````````dat nen phan rang giá rẻ **** can ho go vap - du an quan 9

Chuyên thu mua nhôm, thu mua sắt, thu mua đồng thu mua phế liệu giá cao hơn ngoài thị trường

* PrimeXBT What makes it so special and is it worth to try it out?